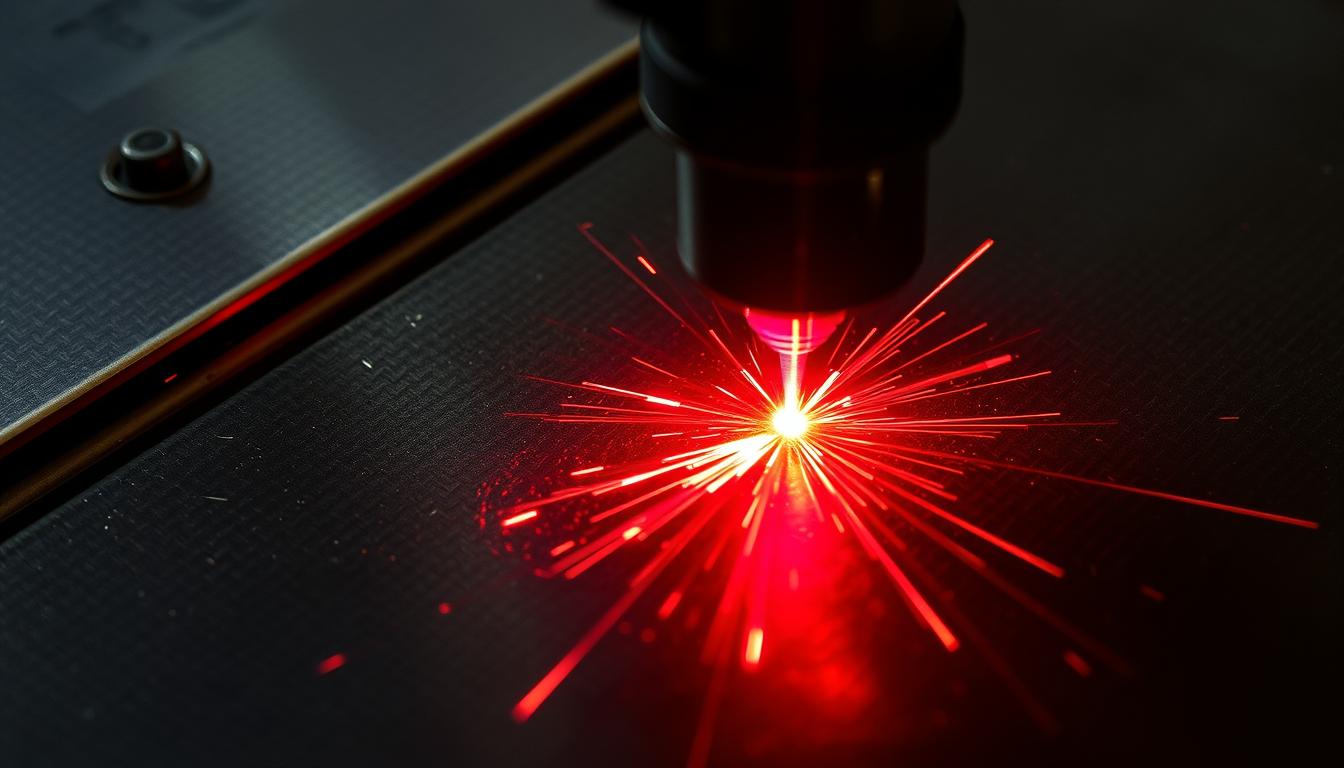

Being able to control the depth of laser engraving on iron is key for many industries. This includes the automotive, manufacturing, and aerospace sectors. Deep laser engraving uses a focused light beam to create 3D designs, like logos and text, in metals with great precision.

Pulsed fiber lasers are best for deep engraving on iron. They have high peak power, allowing them to engrave up to a few millimeters deep. This is much deeper than standard laser engraving, which only goes a few microns deep.

This deep engraving is used for many things. It’s used for deep logo engraving, stamping plate engraving, and mold insert engraving for car parts.

But, deep engraving on stainless steel needs care to avoid rust. The process removes the protective oxide layer. Also, the metal’s alloy and laser settings can change the engraving color.

Mastering deep laser engraving on iron is about finding the right balance. It’s about power, time, and speed to get the right depth and quality. It also involves safety and what to do after engraving. Knowing the basics and important settings is vital for industries wanting to use deep metal engraving.

Understanding Deep Laser Engraving Fundamentals

Laser engraving is used in many fields, from marking to making permanent designs. It goes deeper than standard engraving, reaching several millimeters into the surface.

Difference Between Standard and Deep Engraving

Standard engraving makes shallow marks, while deep engraving creates deep designs. Deep engraving uses a laser to vaporize material, making designs stand out.

Achievable Depth Ranges in Metal

The depth of laser engraving on metals depends on the machine and design. It usually goes a few millimeters deep. Metals like steel and aluminum are often engraved for durability.

Material Removal Process

Deep laser engraving on metals vaporizes the surface, creating deep designs. This method works on many materials, including steel and aluminum, based on their vaporization temperatures.

| Material | Vaporization Temperature (°C) |

|---|---|

| Aluminum | 2327 |

| Copper | 2595 |

| Iron | 3000 |

| Lead | 1750 |

| Magnesium | 1110 |

| Zinc | 906 |

The engraving can go up to 0.5mm deep, making marks stand out. Laser engraving can create different effects, from simple contrasts to detailed black and white designs.

Key Parameters for Controlling Engraving Depth

Getting the right engraving depth on metals is key in laser technology. Important factors include laser power, lens choice, scanning speed, and part temperature. By tweaking these, experts can make sure surface marking on metals is precise and durable.

First, more laser power means deeper engravings. Experts say you need at least 100W for fast and deep cuts. The lens you pick also affects how fast and deep you can engrave, with smaller lenses being better for deeper laser technology.

- Slower scanning speeds help put more energy on the metal, leading to deeper engravings.

- Preheating metals like aluminum can make engravings up to 40% deeper.

- Longer line widths usually mean faster engraving compared to shorter lines.

By adjusting these factors, pros can control engraving depth well. This ensures durable marking and top-notch results on many metal types. Knowing how to balance these elements is crucial for great laser engraving.

Laser Engraving on Iron and Metal Surface Considerations

Laser engraving on iron or stainless steel comes with its own set of challenges. The metal’s protective layer is removed during engraving, making it more prone to corrosion. It’s vital to prepare the surface well to get clean, high-quality results.

Surface Preparation Requirements

Before engraving, the metal surface must be cleaned and degreased. This step is key to ensure the laser works well, creating sharp marks. It also helps avoid any dirt or residue that could mess up the engraving.

Protective Measures for Preventing Corrosion

After engraving, it’s important to protect the metal from corrosion. Post-processing treatments, such as painting or chrome plating, can seal the engraved area. This helps keep the metal looking good for a long time.

Post-Processing Treatments

The laser settings can change how the metal looks after engraving. Faster settings might leave the stainless steel looking blackened. But slower, more careful settings can give a cleaner finish. Finding the right balance is key to getting the look you want.

Having good exhaust systems is also crucial. They help keep the air clean and control the temperature during iron etching. This is important for safety and to prevent damage from the laser’s heat.

Equipment and Technology Requirements for Deep Metal Engraving

Deep metal engraving needs the right tools and tech. Fiber lasers with at least 20 watts are key for iron and stainless steel. A 50-watt laser can make the process even faster.

Galvo-based lasers are better than gantry-style ones for speed. They can be 10 to 30 times quicker. Machines for deep engraving need to be in a controlled space because the process takes a long time.

| Laser Type | Suitability for Metal Engraving |

|---|---|

| Fiber Laser | Highly suitable due to high power density and ability to work with reflective materials |

| CO2 Laser | Can be used for metal engraving, but not as efficient as fiber lasers |

| Diode Laser | More affordable entry-level option for metal engraving |

Keeping workers safe and the air clean is vital. Class-1 laser safety enclosures and fume extractors are must-haves. Fiber lasers are better for deep metal engraving than CO2 lasers because they have more power and work well with shiny materials.

Choosing the right laser tech, power, and tools is key for top-notch, deep metal engravings. By picking the best laser technology, precision engraving, and industrial marking options, makers can open up new ways for personalization, customization, and lasting marks in many fields.

Conclusion

Deep laser engraving on iron and metals creates lasting marks for many uses. It needs careful planning of laser power, optics, speed, and material. Higher-powered lasers can engrave deeper, but time, finish, and after-care are key.

Fiber laser systems are getting better, making them great for deep metal engraving. Laser engraving on iron and metals is popular for many reasons. It makes lasting, clear marks, useful in many fields like metal engraving for cars, planes, medical, jewelry, and energy.

Deep laser engraving lets us control the depth of marks on metals. This opens up new uses for industries needing permanent, top-notch marks. As tech improves, we can expect even better metal engraving options.

Leave a Reply