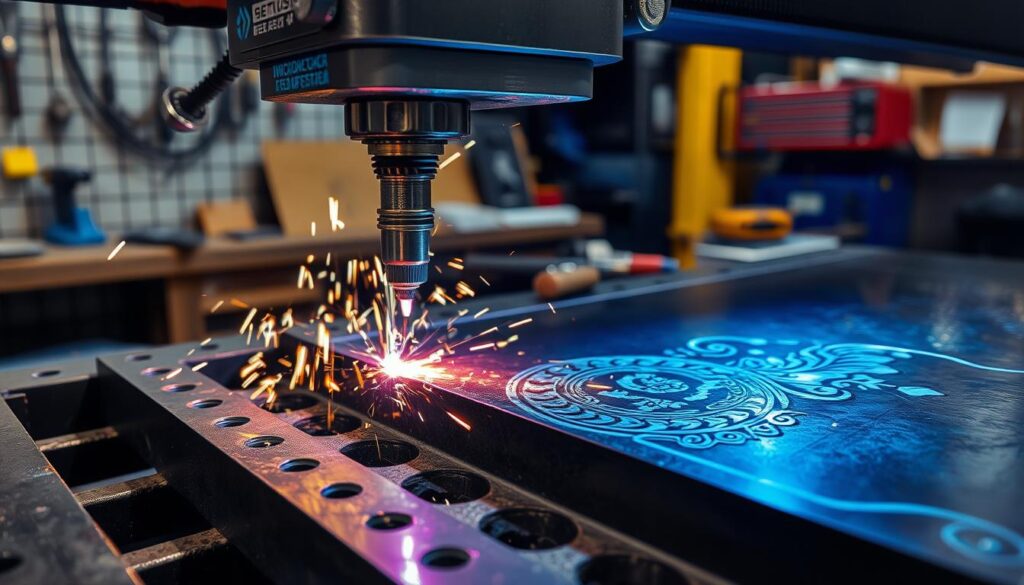

Metal laser engraving is a modern method for making detailed designs on iron and other metals. It uses a focused light beam to mark metal surfaces without touching them. This method is very accurate and fast.

To create an engraving on iron, a laser beam is directed at the metal. The metal absorbs the light, turning it into heat. This heat causes the metal to vaporize, creating a design.

The laser’s speed, power, and focus can change the engraving’s depth, size, and darkness. This non-abrasive technique is great for both art and industrial needs. It allows for detailed and complex designs with high precision.

Understanding Metal Laser Engraving Fundamentals

Laser engraving on metal, like iron, mixes the laser’s energy with the metal’s properties. This interaction is key to grasping metal laser engraving basics.

Basic Principles of Laser-Metal Interaction

A laser beam hitting a metal surface causes it to heat up, melt, and vaporize. How well this happens depends on the metal’s ability to absorb the laser, its heat spread, and how easily it vaporizes. Iron, for example, absorbs laser energy better than some metals, making it easier to engrave.

Types of Laser Technology for Metal Processing

Fiber lasers are best for laser marking iron and other metal engraving tasks. They have shorter wavelengths that metals absorb well. On the other hand, CO2 lasers are not as good for direct metal engraving without special coatings or treatments.

Power and Wavelength Requirements

For iron laser etching, you need laser power between 20W and 100W. This depends on how deep and fast you want the engraving. The most effective wavelength for metal engraving lasers is around 1064nm, in the near-infrared spectrum.

Knowing how laser-metal interaction works, the right laser tech, and the needed power and wavelength is vital. It ensures precise and quality laser engraving on iron and other metals.

Laser Engraving on Iron: Equipment Setup and Parameters

Laser engraving on iron needs careful thought. Iron’s high vaporization temperature and reflectivity require more laser power. The right laser equipment and settings are key for precise iron markings.

Fiber lasers work best for engraving metals like iron. They emit wavelengths that metals absorb well, making engraving more efficient. To start, place the iron on the engraver, adjust the laser head, and set power, speed, and frequency.

For iron, use 50-100% laser power and slow speeds for better energy absorption. Set the focal length for the right engraving depth. Always wear laser safety glasses and ensure good ventilation.

The xTool F1 or F1 Ultra are great for metal engraving, including iron. They have advanced features like protection systems and precise focus. These lasers also cool and ventilate well, ensuring reliable iron marking.

Choosing the right laser and adjusting settings unlocks iron’s full potential. This leads to custom, durable markings for many uses. From industrial tags to personal items, laser engraving on iron is versatile.

Essential Steps for Precise Metal Laser Adjustment

To get precise laser engraving on iron, you need to focus on surface prep, focus, and power. Learning these steps is key to mastering laser annealing iron surfaces and laser coloration iron.

Surface Preparation Requirements

Clean the iron surface well before engraving. Use isopropyl alcohol to get rid of dirt, grease, and oxide. For shiny iron, apply a metal marking spray to help the laser work better.

Focus and Alignment Techniques

Getting the laser beam right is vital for clear engraving. Use the laser’s auto-focus or adjust it manually to hit the iron spot-on. Aligning it well stops distortion and uneven lines.

Speed and Power Settings Optimization

For laser annealing iron surfaces and laser coloration iron, start with 60-70% power and 20-30 mm/s speed. Adjust these for the engraving depth and detail you want. Test on scrap iron to perfect your settings.

Keep an eye on the engraving and tweak as you go for top quality. By following these steps, you can make custom, lasting engravings on iron.

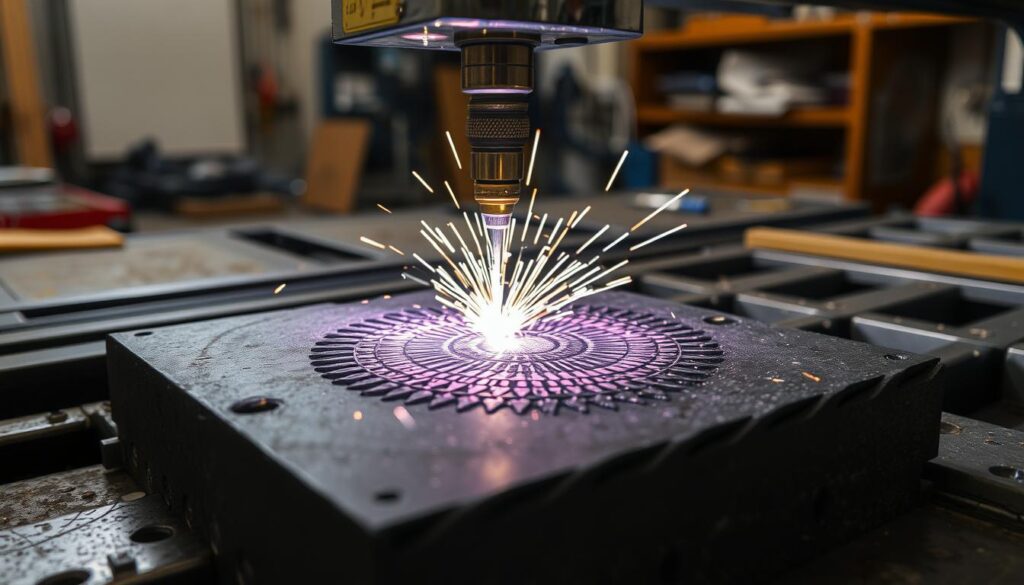

Advanced Techniques for Custom Metal Patterns

Laser engraving on iron opens up a world of custom and intricate patterns. There are advanced methods that can elevate your metal engraving. These techniques can make your designs stand out.

Multi-pass engraving is a powerful method. It involves the laser making multiple passes to create deeper cuts. This is great for 3D effects and textured surfaces. Try changing the power levels between passes to add depth to your designs.

Using laser engraving with annealing adds color changes and unique effects. It involves carefully applying heat to the iron. Adjust the laser’s focus and wavelength to get the desired look.

- Try different focal lengths for various textures and depths. Shorter lengths are for finer details, while longer lengths are for bigger designs.

- Use vector graphics software for intricate designs. It helps create complex patterns that can be precisely engraved.

- Try cross-hatching or dot matrix patterns for striking effects. They add unique visual interest to your metal surfaces.

- For curved or uneven surfaces, use a rotary attachment. It ensures even engraving across the piece.

For big projects, use tiling techniques. It breaks down designs into sections that can be pieced together. This way, you can create large engravings even if your machine can’t handle them.

Advanced users might want to play with pulse frequency. Changing the pulse rate can improve the balance between speed and quality. It depends on your project’s needs.

Remember, iron is heat-sensitive. Adjust the cooling time between engraving passes. With these advanced techniques, you can create endless custom metal patterns.

Conclusion

Laser engraving on iron is a precise way to make lasting marks and designs. It needs careful thought about iron’s nature, the right laser tech, and fine-tuning settings. Fiber lasers work best for iron because of their wavelength and power.

Getting good results in iron engraving means preparing the surface well, focusing the laser right, and setting the speed and power just so. With advanced methods, you can make intricate patterns and textures on iron. As tech gets better, laser engraving on iron opens up new chances for both work and art, giving lasting, top-notch results for many projects.

Laser engraving on iron, or iron laser etching, is getting more popular. It offers unmatched precision and customization. With laser tech’s power and accuracy, many industries can make detailed, lasting marks on iron, from parts to art.

Leave a Reply