UV technology changes the game for printing on iron, making colors last longer and look better. UV-curable inks dry instantly when hit with UV light. This creates a strong, bright print on iron that doesn’t soak in.

This method also makes the ink stick better to iron and keeps colors from fading. It’s perfect for keeping prints looking great over time. This is why UV printing is great for businesses and custom metal projects.

Also, UV printing is better for the planet. It releases fewer harmful chemicals than old printing ways. This makes it a green choice for companies wanting to be eco-friendly.

In short, UV technology in iron printing is a big leap forward. It brings better color, durability, and eco-friendliness. This tech is opening doors for top-notch metal prints in many fields, from fashion to industry.

Understanding UV Printing Technology Fundamentals

UV printing technology has changed the digital printing world. It offers vibrant, durable, and versatile prints. At its heart is ultraviolet (UV) light, key in curing special inks.

The Science Behind UV Light Curing

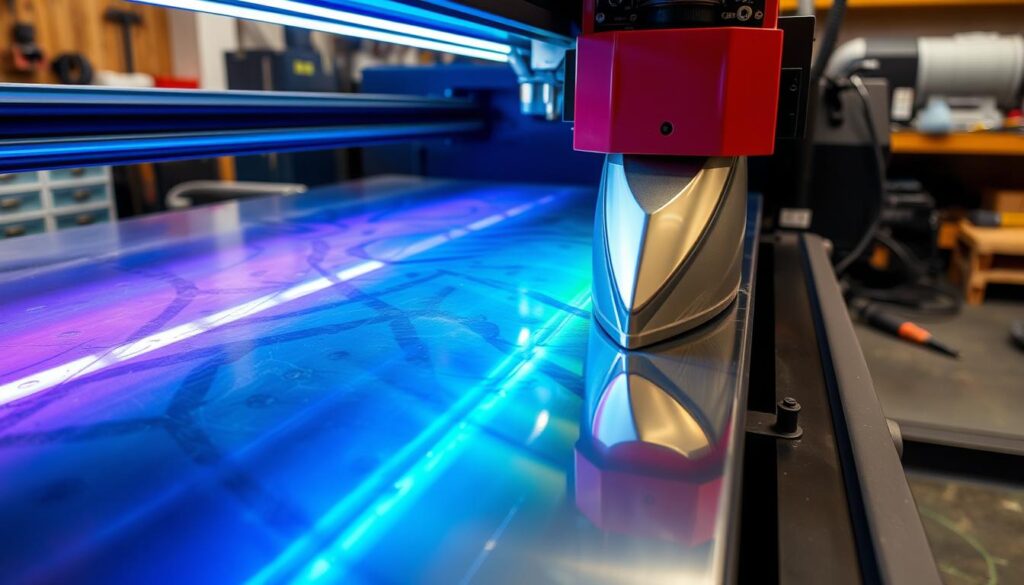

The UV printing process uses inks with photoinitiators. These molecules react when hit by UV light. When ink meets UV light, it instantly cures and solidifies.

Components of UV Printing Systems

UV printing systems have important parts. These include precision print heads, UV lamps, and special inks. Together, they ensure top-notch print quality and durability.

Benefits of UV-Curable Ink Formulations

UV-curable inks have many benefits. They dry instantly, stick well to many surfaces, and show bright colors. Plus, using LED lamps saves energy and is good for the planet. This makes UV printing great for digital printing and custom clothes.

Digital UV Printing on Iron: Process and Applications

The world of printing has seen a big change with digital UV printing on iron. This new tech lets us make bright, photo-quality prints on metal. It opens up many new possibilities for different industries.

The digital UV printing on iron starts with getting the metal ready. This might mean flame treatment or primer to help the ink stick. Then, special print heads put down UV-curable ink on the iron. Right away, UV light makes the ink strong and beautiful.

This tech is used in many fields, like cars, appliances, and metal signs. Digital UV printing on iron lets us make detailed designs and photos. It’s great for making durable prints on metal that can handle wear, chemicals, and weather.

| UV Printing Machine | Key Features | Recommended Applications |

|---|---|---|

| KINGT Flatbed UV Printer | – Prints directly on metal surfaces like aluminum plates, stainless steel, and metal signs – Offers individualization, rich color options, and strong artistic effects | – Customized metal giftware – Personalized metal signage – Decorative metal box printing |

| KGT-1016 UV Printer | – Affordable and easy way to personalize customization for iron, aluminum sheets, stainless steel, and more – Produces high-quality, vibrant prints | – Customized metal plates and sheets – Personalized metal home decor – Industrial metal product printing |

| KGT-2513 or KGT-2033 UV Flatbed Printers | – Recommended for UV printing on metal plates – Offer versatile printing capabilities and high-quality results | – Metal signage and displays – Custom-printed metal furniture and accessories – Promotional metal products |

The secret to great digital UV printing on iron is in the details. From getting the metal ready to applying and curing the ink. This tech lets businesses get creative, personalize, and grow. It changes how they print and make metal products.

Color Stability Enhancement Through UV Technology

UV curing technology is key in keeping colors bright and stable on iron surfaces. It instantly turns liquid ink into solid, stopping colors from spreading. This quick process also stops pigments from fading, which is great for metal prints facing the outdoors.

Chemical Reactions in UV Curing Process

The UV curing process starts a chain of chemical reactions. These reactions link the ink molecules together, creating a strong layer on the print. This happens when UV light meets the ink’s photoinitiators, starting a fast polymerization that solidifies the ink right away.

Prevention of Color Fading and Oxidation

UV-cured inks create a shield that fights off chemical damage, UV rays, and the weather. This shield keeps the pigments from fading or oxidizing, keeping the colors bright and rich for a long time.

Impact on Long-term Color Retention

Research shows UV-cured prints on metal, like iron, stay colorful and vibrant for much longer than regular prints. The lasting quality of UV-cured inks ensures the design stays sharp and clear, making it perfect for where color staying power is essential.

Advanced UV Curing Systems for Metal Surfaces

Advanced UV curing technology is changing the game for printing on metal. It brings better print quality, durability, and efficiency. This tech is key for on-demand garment decoration and digital direct-to-garment printing.

These systems use different UV wavelengths for deep curing. They also have inert gas environments to stop oxygen from affecting the print. This makes the surface harder and more resistant to chemicals.

LED UV curing technology is becoming popular for metal printing. It’s energy-efficient and doesn’t heat up the substrate too much. Modern systems can control the curing intensity and time. This lets you fine-tune the process for different inks and metal types.

| Feature | Benefit |

|---|---|

| Combination of UV wavelengths | Thorough curing of surface and deeper ink layers |

| Inert gas curing environment | Improved surface hardness and chemical resistance |

| LED UV curing technology | Energy efficiency and reduced heat output |

| Precise curing control | Optimization for specific ink formulations and metal surfaces |

These UV curing systems for metal surfaces bring many benefits. They make production faster, prints better, and last longer. These are key for the on-demand garment decoration and digital direct-to-garment printing markets.

Quality Control and Performance Metrics in UV Printing

In the world of digital UV printing on iron, photo-quality prints on fabric, and personalized clothing design, quality is key. UV printing brings many benefits like better color, durability, and eco-friendliness. A strong quality control system is vital for reliable results.

Color Density Measurements

Color density checks are a main part of UV printing quality control. Spectrophotometers measure color density on various materials, including metals. These tests ensure colors look right and stay consistent.

Durability Testing Methods

Testing how well UV-printed items last is important. Tests like abrasion and chemical resistance check how they hold up. These tests help make sure prints stay looking good over time.

Surface Adhesion Analysis

For personalized clothing design and metal prints, checking how well they stick is crucial. Tests like cross-hatch and pull-off strength check the bond. This ensures prints stay looking great and last long.

Other important checks include gloss and color gamut tests. These ensure UV-printed items look as good as they should. By using these quality control steps, makers can keep high standards. They deliver top-notch digital UV printing on iron, photo-quality prints on fabric, and more.

Conclusion

Digital UV printing on iron has seen big improvements thanks to UV curing tech. This tech makes colors stay bright, prints last longer, and details are sharp. Unlike old printing ways, UV printing cures instantly and uses strong inks.

This means prints don’t fade, get worn out, or change color over time. They stay vibrant and eye-catching for a long while.

UV printing can be used on many metal types, opening doors in fields like cars and custom metal art. As UV tech gets better, with energy-saving LEDs and better controls, UV printing on iron will get even better. It will become a top choice for decorating surfaces in a green way.

This big step forward in metal printing brings beauty and lasting quality. It meets today’s needs for high-quality, durable, and attractive prints on iron.

Leave a Reply