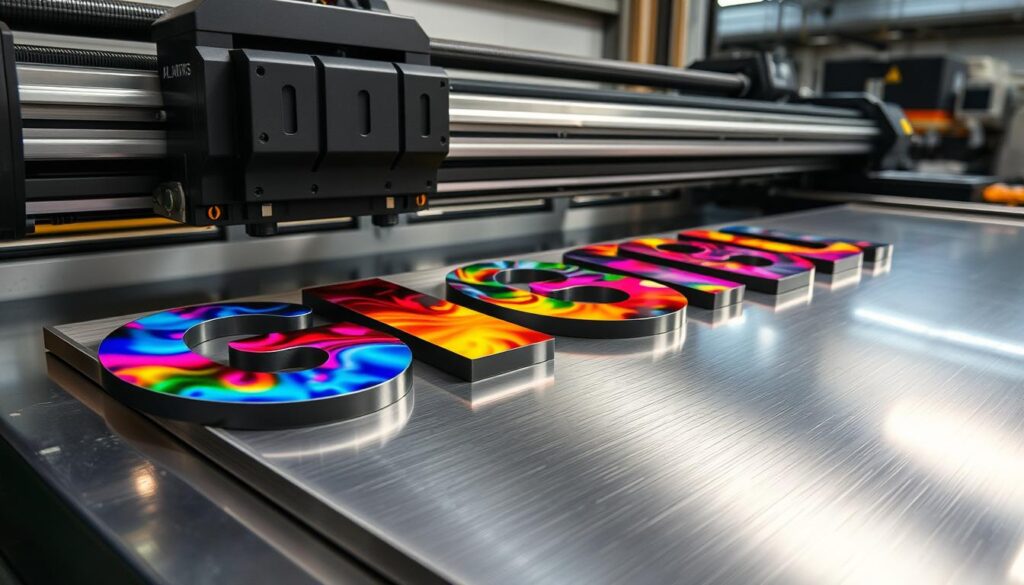

UV printing uses ultraviolet light to instantly cure ink on metal. This makes metal signs durable and eye-catching. It’s a top choice for making high-quality metal signs.

Digital UV printing works on metals like iron, aluminum, stainless steel, and copper. It creates sharp, detailed, and vibrant images. These images don’t fade or weather easily.

UV curing makes the prints last a long time. This is great for both indoor and outdoor signs. The UV flatbed printing technology gives a smooth, even finish. This results in professional-looking signs.

UV curing technology helps metal sign makers work faster. They don’t need extra coatings or laminations. This saves money and is better for the environment.

Understanding the Fundamentals of UV Metal Sign Printing

UV inkjet metal decoration, UV ink adhesion on metal, and industrial UV printing are key to making top-notch metal signs. The science behind UV curing technology is crucial. It uses photochemical reactions from UV light for instant curing and durability.

This method also makes colors pop on metal surfaces. It’s all about quick curing, lasting colors, and scratch resistance.

The Science Behind UV Curing Technology

UV curing tech uses special inks that harden fast under UV light. This turns liquid ink into a solid, lasting layer on metal. A UV printing system includes UV lamps, special inks, and flatbed printers.

These are made for the unique needs of UV printing on metal.

Key Components of UV Printing Systems

- UV lamps that emit high-intensity ultraviolet light to cure the ink

- Specialized UV inks formulated for optimal adhesion and durability on metal surfaces

- Advanced flatbed printers engineered for industrial-grade UV inkjet metal decoration

Advantages of UV Printing for Signage

UV printing has many perks for metal signs. UV inks cure instantly, making prints scratch-resistant and fade-proof. They also last through weather changes.

The bright colors from UV printing grab attention. This makes metal signs eye-catching. Plus, UV printing is better for the environment, releasing fewer harmful chemicals.

Essential Materials and Equipment for Metal Sign Production

Creating top-notch metal signs requires the right materials and tools. Direct-to-substrate UV printing is a favorite method. It lets businesses print bright, lasting graphics on metals like aluminum, stainless steel, copper, and brass.

The main tools for making metal signs include flatbed UV printers, special inks, and tools for applying primer. You also need curing lamps. It’s important to work in a well-ventilated area and wear protective gear. Depending on the metal, you might need to clean and sand it first. This helps the ink stick better and improves print quality.

| Equipment | Description |

|---|---|

| Flatbed UV Printers | These printers are made for printing on flat, hard materials like metal. They produce high-quality, detailed prints. |

| UV Inks | UV-curable inks are key for printing on metals. They stick well, last long, and look great even in bad weather. |

| Primer Applicators | These tools help apply UV primers to metal. This makes sure the ink sticks well and the print looks great. |

| Curing Lamps | UV curing lamps harden the inks right away. This makes the metal signs tough and resistant to scratches. |

For a smooth metal sign production process, consider getting surface prep tools and cleaning agents. Also, don’t forget protective gear like masks and gloves. With the right tools and materials, businesses can make Direct-to-substrate UV printed metal signs that look amazing and last a long time.

Digital UV Printing on Iron: Process and Techniques

The world of metal sign production has changed a lot with digital UV printing. This new tech makes high-quality, custom metal signs that grab attention. The metal surface is carefully prepared for the UV inks to show off their bright colors.

Surface Preparation Requirements

Getting a smooth finish on metal is key for UV flatbed printing. First, the metal is cleaned to get rid of dust, oils, and other stuff that might mess with the ink. This step is important for the best results.

Primer Application Methods

Some metals need a special primer to stick the ink better. There are different ways to apply it, like wiping or removing extra primer. This makes sure the ink sticks well and looks great.

Print Head Height Adjustment

When UV printing on metal, being precise is everything. The print head must be set just right to get the ink on spot. This is how you get the best quality and colors for your metal signs.

Learning these techniques opens up a world of creative options for metal signs. With the right tools and care, you can make unique and eye-catching metal decorations.

Design Considerations for Metal UV Printing

Designing for UV printing on metal requires careful thought. Metals reflect light, making it hard to get vibrant prints. You need to manage colors well, focus on detail, and use special software.

Color Management on Metallic Surfaces

Metal surfaces change how we see colors because of their shine. To get the right colors, you must manage them carefully. Adjust color profiles and check color accuracy during printing.

Resolution and Detail Requirements

For metal UV printing, high-resolution designs are key. You need sharp details and patterns for striking metal signs. Use at least 1220 x 720 DPI to get the best quality.

Software and File Preparation

Special software like Adobe Photoshop and Illustrator is vital. They help manage colors and adjust images. Also, they ensure your artwork stays sharp when scaled. Good file prep is crucial for great UV prints.

Leave a Reply