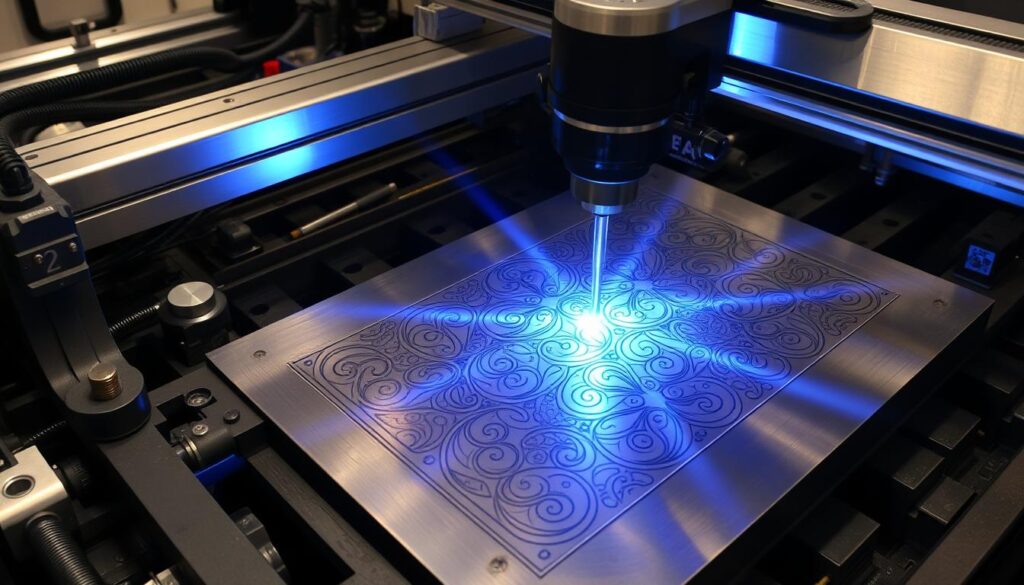

Laser engraving on iron is a cutting-edge method. It makes permanent marks on metal parts with barcodes, labels, and more. This tech is used in many fields like cars, manufacturing, and metal processing.

Fiber lasers are the top choice for metal engraving. They are fast, precise, and efficient. They work well on iron and other metals.

The depth of laser engraving on iron can be from 0.0001 to 0.005 inches. Deeper engravings go beyond 0.005 inches. This depth is key for meeting standards or making engravings readable after processing.

Laser engraving’s flexibility lets manufacturers tailor their marking needs. This meets the specific demands of different industries.

Understanding Laser Engraving Technology for Metal Processing

Laser engraving has changed how we work with metal. Fiber lasers are now the top pick for engraving iron and other metals. They use a special light to engrave directly on iron, stainless steel, and aluminum.

CO2 lasers are not as good for engraving metal but work for marking coated metals. Diode lasers are cheaper and good for simple iron engraving. But they can’t match the power and precision of fiber lasers.

Power and Precision Considerations

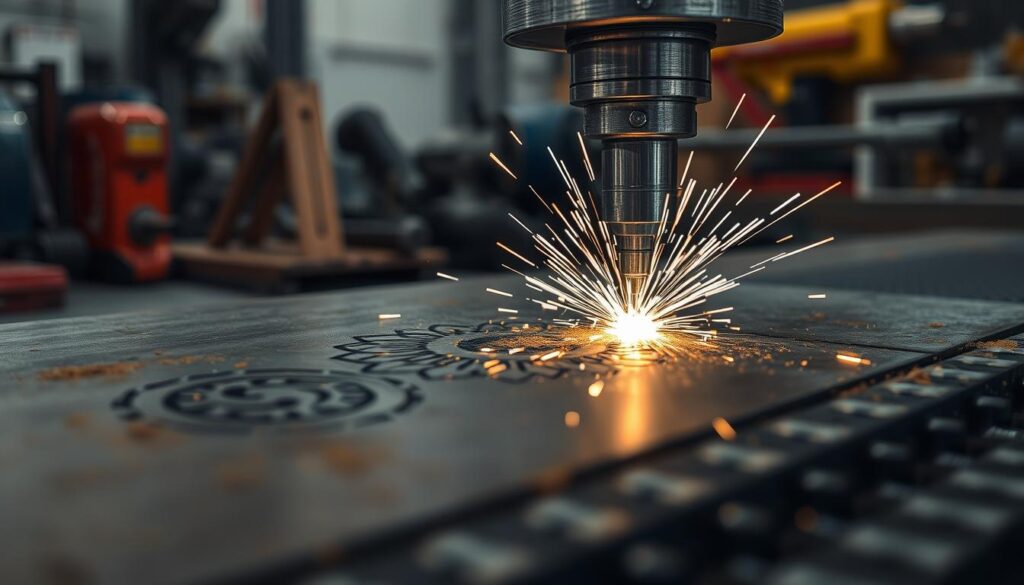

The power of laser engraving machines is key. It affects how fast and deep they can engrave. More powerful lasers work faster and make deeper marks, perfect for big custom laser engraved iron projects.

The quality of the engraving also depends on the laser’s precision. This comes from the optical parts and how well they focus the beam. All these factors make the laser iron personalization process more accurate.

Industrial lasers come with safety features, cooling systems, and automation. This ensures they work well and reliably in busy production settings.

Laser Engraving on Iron: Methods and Techniques

Precision laser engraving on iron is a key method in making things. It uses three main ways: laser etching, laser engraving, and laser annealing. Each one makes different marks and changes the iron in unique ways.

Laser Etching: This method changes the iron’s surface to make black and white marks. By adjusting the laser settings, you can get sharp, lasting engravings. Laser etching is great for clear labels or logos on iron parts.

Laser Engraving: This method burns away layers of material to create deep marks. Laser engraving makes detailed, three-dimensional designs that last even in tough conditions. It’s used for things like serial numbers and laser marking iron in many industries.

Laser Annealing: This method makes black marks inside the iron without changing its surface. It keeps the iron’s natural protection while adding cool designs. Laser annealing is perfect for fancy iron laser branding and marks that show if something has been tampered with.

These precision laser engraving on iron methods can be changed with the same laser by tweaking settings. This flexibility lets makers choose the best method for their needs. Whether it’s for clear labels, lasting marks, or fancy designs, there’s a way to do it.

Industrial Applications and Market Sectors

Laser engraved iron products are used in many industries. In the automotive industry, they mark VIN numbers and barcodes. They also add logos to parts. This makes identification permanent and secure.

The manufacturing and fabrication sectors use laser engraving too. It helps identify parts and prevent counterfeiting. In the primary metals processing industry, it’s used for quality control and product identification.

Laser engraving systems fit well into production lines. They have features like automated doors and robot compatibility. This makes them a great choice for many industries.

Automotive Industry Implementation

In cars, laser engraving marks VIN numbers and barcodes. It also adds logos to parts. This makes identification precise and secure.

Manufacturing and Fabrication Uses

Laser engraving is key in making and fixing things. It’s used for part identification and to prevent counterfeiting. It makes durable and precise marks on metal.

Primary Metals Processing

Laser engraving is big in metal processing. It’s used for product ID and quality control. It makes marking metal products efficient and reliable.

Benefits and Advantages of Industrial Iron Laser Marking

Industrial iron laser marking has many benefits. It creates permanent, high-contrast marks that last a long time. These marks can withstand wear and surface treatments, making them great for identifying metal parts.

Laser engraving is non-contact, which means it doesn’t damage the material. It works well on curved or irregular surfaces. Plus, laser systems need little upkeep, use less energy, and don’t need consumables. This makes the process efficient and cost-effective.

Laser engraving can mark many types of information. This includes simple text, complex barcodes, and logos. It does so with high precision and can be repeated. This is especially useful in industries like automotive, aerospace, and electronics, where accuracy is key.

| Benefit | Description |

|---|---|

| Permanent Marks | Laser engraved marks are deeply etched into the metal, resisting wear and surface treatments. |

| Versatility | Laser systems can mark a wide range of information, from text to complex designs, with high precision. |

| Non-Contact Process | The laser-based marking process avoids material deformation, allowing for marking on curved or irregular surfaces. |

| Efficiency and Cost-Effectiveness | Laser systems require minimal maintenance and consume less energy than traditional marking methods. |

The advantages of industrial iron laser iron personalization are clear. It offers permanent, high-quality marks, versatility, and cost-effective operations. As demand for custom laser engraved iron and iron engraving machine solutions grows, this technology will become even more crucial in modern manufacturing and processing.

Conclusion

Laser engraving on iron is now a top choice for marking parts in industry. It’s known for its great versatility, lasting quality, and fast work. The tech keeps getting better, with faster, more precise, and smarter tools for making parts.

As companies focus more on tracking and quality, laser engraving on iron is key. It’s used in car making, metal work, and more. It helps with identifying parts, adding brands, and stopping fake goods.

The future of laser engraving on iron is exciting. New tech and ways to use it will keep it a top choice for making parts. Its ability to be precise and versatile will keep pushing the limits of part marking and identification.

Leave a Reply