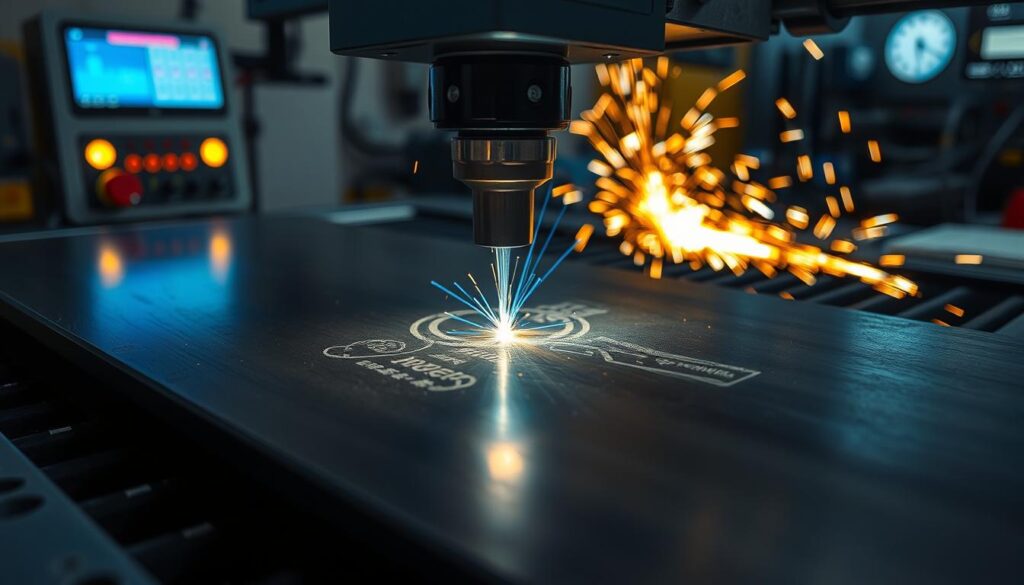

Metal laser engraving uses focused laser beams to mark metal surfaces. It’s key in aerospace, electronics, and automotive for precise engravings. This method ensures accurate engravings on iron without damaging the material.

The laser vaporizes the material, making permanent marks without harming the metal. It’s faster and uses less energy than old methods. Plus, it can etch up to 500 microns deep, offering great detail.

As the industry grows, makers look for new ways to improve iron engraving. We’ll dive into metal laser engraving basics, the parts of laser systems, and advanced techniques. These can make iron markings more precise and high-quality.

Understanding the Fundamentals of Metal Laser Engraving

Laser engraving is a precise method that has changed how we mark and decorate metal. It uses a focused light beam to remove material, making deep, detailed engravings. These engravings are both beautiful and long-lasting.

Key Components of Laser Engraving Systems

Laser engraving systems have three main parts: a laser source, a beam delivery system, and a computer. The laser source, like a CO2 or fiber laser, gives the energy needed to remove material. The beam delivery system makes sure the laser hits the right spot. The computer lets us create detailed designs on metal.

Process Parameters and Their Impact

The quality and depth of laser engravings depend on several factors. These include laser power, speed, and frequency. Changing these settings lets us fine-tune the engraving. For example, more power means deeper marks, and faster speeds make designs more detailed.

Surface Preparation Requirements

Getting the metal surface ready is key for laser engraving. It must be clean and free of dirt, oil, and coatings. This ensures the laser can work well and create the desired engraving.

Laser Engraving on Iron: Essential Techniques and Methods

Laser engraving on iron is a precise and versatile method. It has changed how industries customize, mark, and identify things. Fiber lasers are key in making deep, lasting engravings on iron. By adjusting the laser’s power and the number of passes, experts can create detailed designs, logos, and text.

The first step is to import or create the design using special software. Then, the iron piece is placed in the engraving system for stability and precision. The laser then removes the iron’s surface layer, revealing the material underneath. This method allows for detailed and consistent markings.

After engraving, the iron needs cooling and cleaning to remove debris. This step gives the engraved iron a polished look. It’s important for both the visual appeal and the durability of the markings.

Laser engraving on iron offers endless possibilities for various industries. It’s used for industrial laser marking, laser iron customization, and iron surface marking. It’s perfect for creating unique product identifiers, branding, or decorative designs. This technique’s precision and control make it vital in metal engraving.

Advanced Technologies for Enhanced Iron Marking Precision

The quest for perfect laser engraving on iron has sparked new tech. Fiber lasers stand out, offering top-notch iron marking. They control the laser beam’s pulse, fine-tuning the engraving’s depth and detail.

Fiber Laser Applications

Fiber laser machines are great for engraving metals like aluminum and steel. They make marks that are clear and permanent. These machines can adjust settings for faster engraving on iron.

Pulse Duration Control Methods

Laser etching iron and precision laser engraving get better with pulse control. This lets engravers create detailed designs and serial numbers on iron. The results are clear and last long.

Beam Focus Optimization Strategies

Beam focus is another key area for laser tech. Adjusting the focus improves engraving accuracy and quality. Laser engraving is non-contact, keeping the iron piece safe.

Optimizing Surface Quality and Detail Resolution

To get top-notch high-resolution iron engraving, you need to focus on surface quality and detail. First, make sure the iron surface is clean and ready. This step is key to making the marks stand out.

Adjusting the laser’s power, speed, and focus is also important. These settings affect how deep and clear the engraving will be. It’s all about getting the right balance for the best results.

After engraving, adding a polish or coat can make the detailed iron markings look even better. Using high-resolution settings on the laser is crucial. It helps capture small details and text, making the engraving look sharp and professional.

| Laser Parameter | Optimal Range | Effect on Engraving |

|---|---|---|

| Power | 20W – 100W | Higher power increases depth and width of markings |

| Speed | 7,000 mm/s – 10,000 mm/s | Slower speeds result in deeper, more defined engravings |

| Resolution | 500 DPI or higher | Higher resolution enables finer details and smaller text |

| Pulse Frequency | 10 kHz – 50 kHz | Higher frequencies create smoother, more uniform markings |

By tweaking these settings and using the right prep and post-care, you can get amazing high-resolution iron engraving. Your work will have top-notch surface quality optimization and detailed iron markings.

Conclusion

Advanced laser techniques have changed iron engraving a lot. They bring better precision, durability, and flexibility. Fiber lasers, pulse control, and beam focus have made engravings on iron look better.

These advancements in laser technology help industries make detailed, lasting marks. They’re great for identification, branding, and more.

As laser technology keeps getting better, we’ll see even faster and more detailed engravings. This will make laser engraving the top choice for marking metals.

The ability to make improved iron markings has changed how industries mark metals. It’s now easier to identify, track, and personalize metal items.

Looking to the future, advanced laser engraving techniques will keep changing metal marking. This will lead to more innovation and efficiency in many fields. Laser engraving will stay a key tool in modern making and design.

Leave a Reply