Digital UV printing on iron requires careful surface preparation for top quality and lasting results. Knowing the key steps to prepare an iron surface is vital for successful UV printing. This guide will cover the main considerations and techniques needed for iron surface prep before starting UV printing projects.

UV printing technology has seen a big rise in recent years, with a 17% jump in 2023. This growth is due to UV printing’s eco-friendly nature, high-quality prints, and excellent color fastness. When printing on iron, proper surface prep is crucial for the best results.

Understanding UV Printing Technology for Metal Surfaces

UV printing technology has changed the printing world. It uses special UV-curable inks that dry fast when hit with UV light. This quick drying is great for printing on metal and other surfaces.

Basic Principles of UV Curing Process

The UV curing process uses UV light to harden ink fast. This skips the need for slow drying methods. It makes printing faster and cuts down on waste. The inks stick well to metals like aluminum and stainless steel.

Benefits of UV Printing on Iron Materials

UV printing on metal is very durable. It resists fading, scratches, and moisture. It’s perfect for signs, industrial parts, and car parts because of its bright colors and sharp details.

Types of UV-Curable Inks for Metal

There are special UV inks for metal printing. They stick well, bend without breaking, and resist the weather. You can find inks for hard surfaces, flexible ones, and even ones with metallic or glitter finishes.

Knowing about UV printing and its inks helps businesses make top-notch, lasting graphics on metal. It’s a great way to make your prints stand out.

Essential Equipment and Materials for Iron Surface Preparation

Preparing an iron surface for UV printing needs the right tools and materials. From printing equipment to surface preparation tools, each item is key. They ensure a smooth printing process and top-quality results.

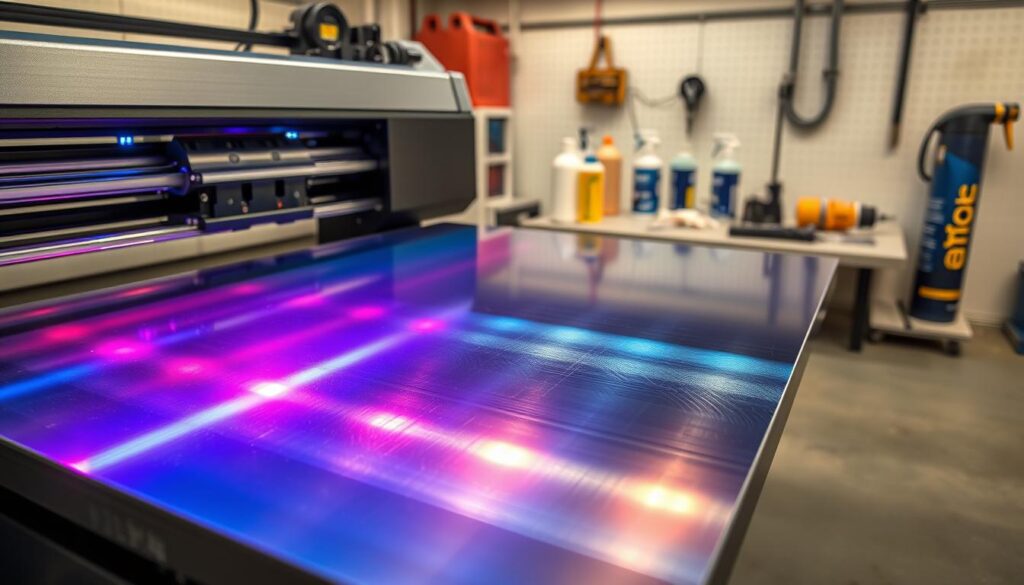

A UV flatbed printer is at the center, printing directly on iron. These machines handle different metals well, offering precise control and consistent results. You also need UV DTF (Direct to Film) film and UV adhesive for durable, bright prints on iron.

A UV curing lamp is also crucial. It cures the UV inks, making prints stick well and last long. Tools like measuring devices, cleaning supplies, and safety equipment help get the iron ready for printing.

The type of paper or film used is very important. It must meet specific needs like high alpha-cellulose content and proper sizing. Buxton paper from Ruscombe Mill is recommended for iron-based printing.

Choosing the right industrial printing equipment, UV printer manufacturers, and surface preparation tools is key. This ensures a smooth UV printing process on iron, delivering quality and durable products.

| Equipment and Materials | Description |

|---|---|

| UV Flatbed Printer | Advanced machine designed for direct printing on metal substrates, including iron. |

| UV DTF Film | Specialized film used for direct-to-film printing on iron surfaces. |

| UV Adhesive | Adhesive formulated for bonding UV-curable inks to iron materials. |

| UV Curing Lamp | Essential equipment for curing UV-curable inks on iron surfaces. |

| Measuring Devices | Tools used for accurate surface preparation and quality control. |

| Cleaning Supplies | Materials for thorough surface cleaning and degreasing. |

| Safety Equipment | Protective gear for a safe working environment during surface preparation. |

| Buxton Paper | Recommended paper for iron-based printing processes. |

Digital UV Printing on Iron: Surface Preparation Steps

Before starting digital UV printing on iron, it’s key to prepare the surface. Cleaning and treating it right ensures the UV inks stick well. This process helps businesses get top-notch, lasting prints on their iron items.

Initial Surface Cleaning Methods

The first thing is to clean the iron surface. This removes dirt, oils, and other stuff. You can use a few methods, like:

- Wiping it with a clean, lint-free cloth and a mild solvent or degreaser

- Scrubbing it gently with a soft-bristle brush to get rid of tough dirt

- Blowing it with compressed air to clear out any last bits

Degreasing and Chemical Treatment

After cleaning, the iron might need more prep for the UV inks to stick. This could mean:

- Using a degreasing agent and letting it sit for a bit

- Washing it off with clean water to get rid of any leftover agent

- Applying a chemical primer or etching solution, following the maker’s guide

Surface Roughness Assessment

Checking the iron’s surface roughness is important. It helps set the right printing settings and ink use. You can use a tester or just look at it. The goal is to match the UV ink’s needs for the best print.

| Surface Preparation Step | Purpose |

|---|---|

| Initial Surface Cleaning | Remove dirt, oils, and contaminants |

| Degreasing and Chemical Treatment | Enhance adhesion of UV-curable inks |

| Surface Roughness Assessment | Determine optimal printing parameters |

Creating the Optimal Working Environment

UV printing on iron surfaces needs a special working environment for the best results. The workspace must be designed with UV printing’s needs in mind.

Environmental controls for UV printing are key. The workspace should have soft light or tungsten lighting to protect the UV-sensitive materials. It should also be clean, flat, and dry for preparing materials.

Having enough space for wet processing is also vital. This includes four photographic dishes and a water source for washing prints. While special ventilation is not needed, keeping the workspace clean and wiping up spills quickly is important. This helps prevent contamination and keeps the print quality high.

| Key Considerations for Optimal Printing workspace setup | Details |

|---|---|

| Lighting | Subdued daylight or tungsten lighting to avoid interfering with UV-sensitive materials |

| Surface Preparation | Clean, flat, and dry surface for preparing materials |

| Wet Processing Area | Four photographic dishes and a water source for print washing |

| Ventilation | No special ventilation required, but maintaining a clean workspace is crucial |

Creating the right working environment for UV printing on iron helps businesses get consistent, high-quality results. It also reduces the chance of printing errors or issues.

Quality Control Measures Before Printing

Ensuring the quality and consistency of UV printing on iron surfaces is key. Before printing, a detailed quality control process is needed. This process checks if the iron surface is ready for printing. It includes tests, adhesion checks, and a final inspection.

Surface Testing Procedures

Surface testing is the base of quality control. It involves checking the iron surface’s cleanliness and uniformity. It also makes sure there are no contaminants or residues left. Surface inspection methods can spot any issues that might affect printing.

Adhesion Testing Methods

Adhesion testing is vital to check how well the UV inks stick to the iron. Different tests, like cross-cut tests or tape pull-off, are used. They ensure the inks will stick well and last through the printing process.

Final Inspection Checklist

- Confirm surface cleanliness and degreasing effectiveness

- Verify proper surface roughness for optimal quality control

- Ensure optimal environmental conditions for printing, including temperature and humidity

- Assess the positioning and alignment of the iron surface within the printing apparatus

- Conduct final visual inspection for any remaining defects or imperfections

By using these detailed quality control steps, businesses can trust in the success of UV printing on iron. This leads to high-quality and lasting results.

Conclusion

Getting iron surfaces ready is key for great UV printing results. By cleaning well, treating the surface right, and checking quality closely, businesses can make the most of UV printing on metal. This makes their prints last longer and look better.

UV printing brings many benefits to different fields. It gives sharper colors, makes prints more durable, and is good for the environment. It’s becoming more popular for ads, displays, furniture, and personalizing products. This meets the need for unique, high-quality, and lasting prints.

Using UV printing on iron helps businesses stand out. They can make eye-catching designs and earn more from custom services and special products. As the print world keeps changing, knowing how to use UV printing on metal will help companies lead the way. They can offer durable printing solutions and custom UV printing that grab people’s attention.

Leave a Reply